The combination of consumer demand and behavior is a moving target. We need only reflect on the impact of the ongoing COVID-19 pandemic to realize just how quickly trends in demand and behavior can shift. As consumers have acclimated to shopping differently (an astonishing 75% of US consumers tried out new shopping behaviors in response to economic pressures), manufacturers are also being forced to make rapid adjustments.1

To meet constant changes in consumer trends and provide customers with new competitive products, organizations are often pressured to take on the roles of both discrete and process manufacturers. As a result, mixed-mode manufacturing has become a critical functionality as manufacturers adapt to the fast-paced shifts that today's market demands. However there remains a major roadblock that has hindered adoption of Industry 4.0 technologies to achieve operational efficiency and business growth: traditional Enterprise Resource Planning (ERP) systems.

The Problem with Traditional ERP Systems

Both discrete and process manufacturing companies have their own challenges and uniqueness. One such example amongst many is shelf life and expiration. Discrete manufacturing processes largely do not have shelf life and expiration issues; whereas for process manufacturing, it is a critical parameter needing systematic tracking. In an industry context, negligence can lead to the compromised quality of reagents produced by a medical manufacturer, or expiry-dated beverages coming from a consumer packaged goods (CPG) manufacturer. Both have the potential to lead to serious health hazards. Organizations struggle to identify systems that can systematically address such unique process challenges.

Traditional ERP systems force manufacturers to choose either a discrete or process manufacturing solution. But that leaves a gaping hole for organizations which must take on the role of both discrete and process manufacturing; they need to meet the constant changes in consumer demand and provide customers with new, competitive products. These traditional systems are also often lagging in some of the most critical components of modern manufacturing: collaboration, integration, flexibility, and data sharing.

Industry 4.0 with Hybrid, Mixed-Mode Manufacturing

Industrial revolutions have impacted the economic and political fortunes of businesses, governments, and human society throughout history. Today we are living in the fourth industrial revolution, or Industry 4.0.

The value of mixed-mode manufacturing along with adoption of Industry 4.0 trends can help organizations lead the way in today's competitive market where we see constant change in consumer demands. Mixed-mode manufacturing delivers results on the most critical metrics—profit, growth, and efficiency—while better enabling them to proactively meet the shifting demands of the market.

Mixed-Mode Under One Roof with Oracle Manufacturing Cloud

As part of a fully integrated supply chain management (SCM) solution, Oracle Manufacturing Cloud provides you the flexibility to run a hybrid, mixed-mode manufacturing environment in the same plant. With Oracle’s mixed-mode manufacturing in the cloud, you can execute both discrete and process manufacturing in the same plant, the same work center, or even the same item. Which method you use is driven by the work definitions defined for the product. This flexibility allows you to determine the best manufacturing method for each stage of production, such as using process manufacturing for bulk processing, and using discrete manufacturing for final packaging.2

Key Benefits & Features of Oracle’s Mixed-Mode Manufacturing

The growing popularity and impact of mixed-mode manufacturing comes with considerable benefits. According to an Industry Week survey,3 the top five of these benefits are:

- Revenue growth

- Distribution and market share growth

- Cost reductions while ensuring quality

- Increased business agility and responsiveness

- Improved operational efficiency and flexibility

It is no surprise then that features and benefits of Oracle’s Mixed-Mode Manufacturing mirror these top benefits, including:

Production execution flexibility - Execute production based on make-to-stock, make-to-order, configure-to-order, engineer-to-order, or make-to-project.

Differentiate by work method - Determine the ideal method for each stage of production such as using process for bulk processing and discrete for packaging.

Consistent processes - Share the same dispatch list, production-reporting, and quality inspections for a consistent shop floor experience.

Cost management - Effectively monitor manufacturing costs and variances by plant and determine the root causes for cost variances.

Closed-loop quality - Capture and analyze quality data. Predict potential issues and take corrective actions throughout the manufacturing lifecycle.

Genealogy and compliance - Capture genealogy for track-and-trace of lot and serialized products to maintain compliance with local regulations.4

Embracing Emerging Technologies

The driving need for manufacturers is finding the right production system to harness real-time data, from flexibility and agility to quality assurance and process controls. Much depends on companies deploying the correct mix of technology and processes to make faster and smarter decisions. Chosen technology is expected to have social network collaboration, mobile capabilities, and smart manufacturing as the basis for effective throughput. Here’s how Oracle incorporates these system expectations:

-

Social Network Collaboration

Oracle Mixed-Mode Manufacturing allows for effective collaboration across your supply chain organization in real time. With the capability to collaborate on specific work definitions and resolve issues quickly, this helps track conversations tagged to a transaction for future reference.

-

Mobile Capabilities

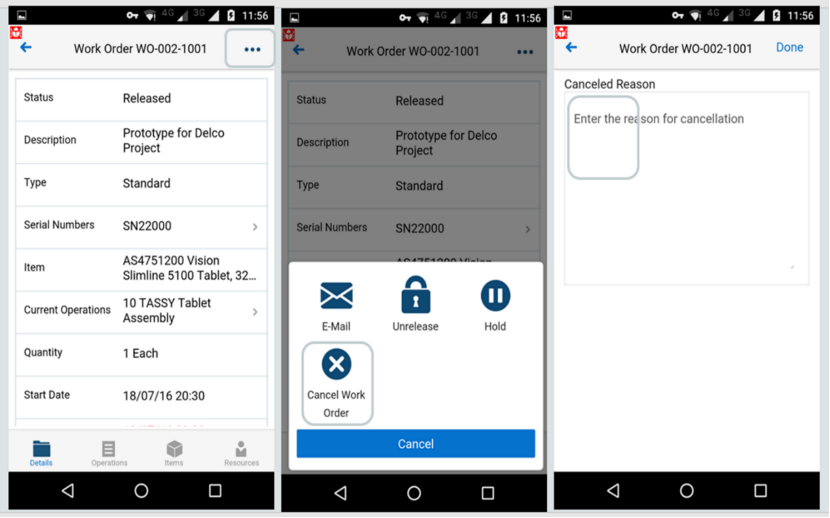

The technology also has a simple and intuitive user interface for shop floor execution. The landing screen of the mobile application provides a simple bird's-eye-view of daily work. You can also use a mobile camera to scan barcodes for searching transactions and perform shop floor transactions (ex. release holds, review past dues, etc.) along with a single click feature to send email notifications.

-

Smart Manufacturing

Oracle’s smart manufacturing solution helps to connect shop-floor data with your manufacturing, maintenance, and planning business systems. It uses artificial intelligence (AI) and machine learning (ML) to contextualize the information and provide actionable insights, optimized production schedules, effective preventive maintenance by enabling you to predict machine failures, eventually avoiding costly downtimes. These deeper insights help in analyzing production efficiency and throughput, increase responsiveness to trends, and improve quality across the board.

Success: Point in Case

Leading Medical Equipment Manufacturer

About the Manufacturer

A medical equipment manufacturer specializing in histopathology and cytology with presence across USA, Europe and Japan. An ISO 13485 / MDSAP certified manufacturer and supplier with FDA registered manufacturing facility utilizing discrete and process manufacturing business processes.

Challenges Manufacturer Faced

- Need of a robust Cloud ERP system to support both discrete manufacturing (for medical equipment) and process manufacturing (for reagent solvents) effectively.

- Integrating 3 disparate Oracle Cloud applications along with multiple 3rd party systems to support real time transactions using 20+ complex integrations. Also supported heavy custom reporting needs.

- SCM – Complex integrated solution between Oracle Supply Chain, Warehouse Management System and 3rd party Shipping/TMS (Transportation Management System) systems.

- CX - Accommodate complicated front-end UX requirements and bugs with newly released products.

Solution

- Implementing business and system processes around Procure to Pay, Plan to Produce, Quote to Cash, Acquire to Retire & Financial Accounting & Reporting processes using Cloud ERP, SCM & CX applications of Oracle.

- Deploying mixed mode manufacturing using Oracle Manufacturing Cloud to support discrete and process manufacturing business processes.

- Integration with 3rd party barcode scanning software for ease of adoption of mobile (handheld device) capability effectively.

- Utilizing Oracle PaaS for designing complex data transformation, tracking & error handling scenarios for interfaces.

Driving Competitive Advantage with Harmony

Achieving harmony in your mixed-mode environment is critical. With the proper systems and support in place, you can turn your discrete and process manufacturing challenges into seamless processes that work collaboratively under one roof.

Below are the top 10 key starting points to get you moving on your journey to driving competitive advantage and achieving manufacturing harmony at your organization.